Hydraulic CNC Press Brake 40T1600 3mm Carbon Steel Stainless steel

Bending CNC Hydraulic Bending TP10S Controller

The oil cylinder of this machine is 40T, and the length of the

table is 1600mm. Its effective working length is up to 1600mm,

close to 5 feet, and the maximum thickness of carbon steel that can

be processed is 3.1mm, and the thickness of stainless steel is

1.6mm. It is equipped with TP10S controller system, which is

capable of angle programming, easy and convenient to operate.

The standard cofiguration:

Main motor, Siemens, Germany

Oil pump, Sunny, USA

Cylinder, Jining Taifeng, China

Servo main motor (optional), Inovance, China

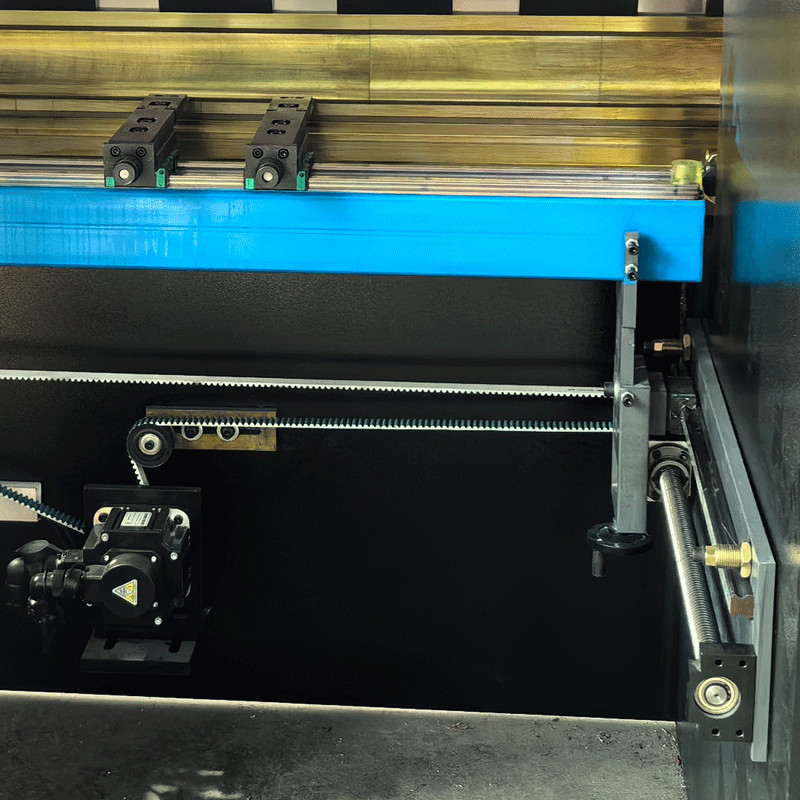

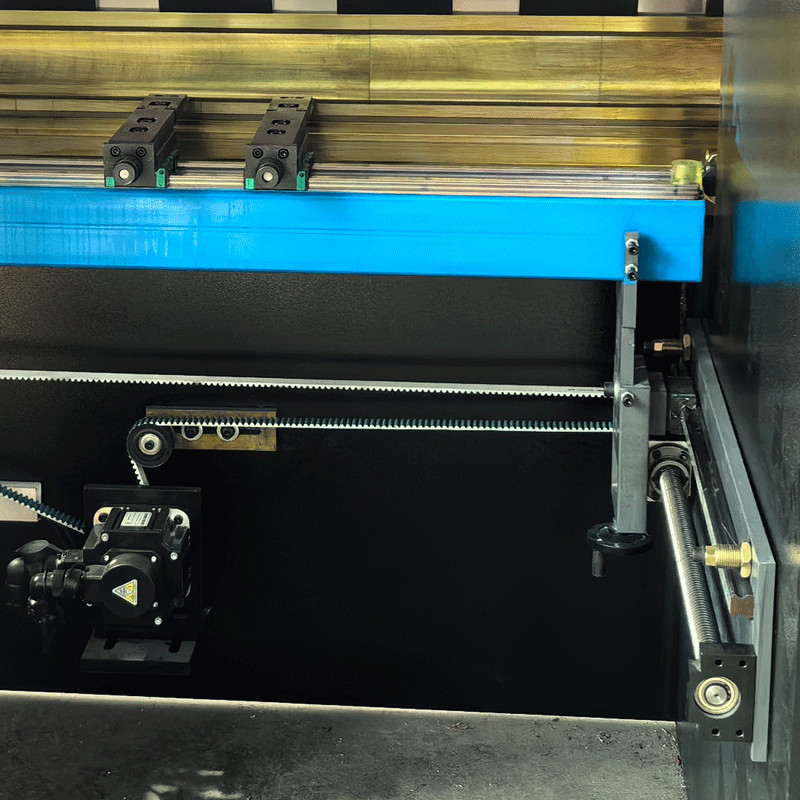

Ball screw, Hiwin, Taiwan

Linear scale, GIVI, Italy

Tubing, EMB, Germany

Seal, Japan

Foot switch, Kacon, Korea

RV reducer motor working table compensation (Optional)

Compensation device (Optional)

Laser protection (Optional) SDKELI or IPG

Light curtain protection (Optional)

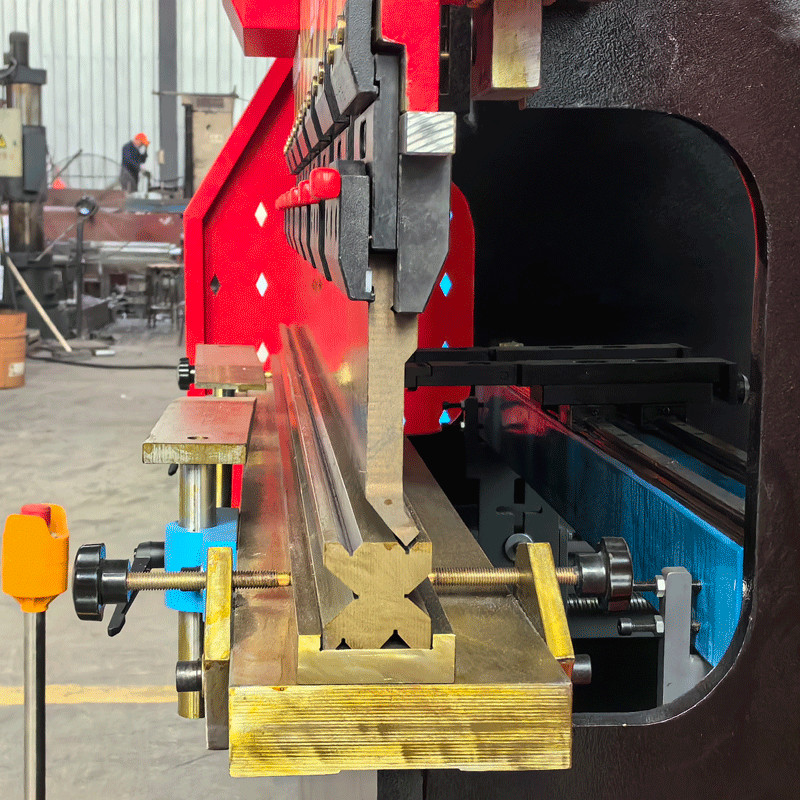

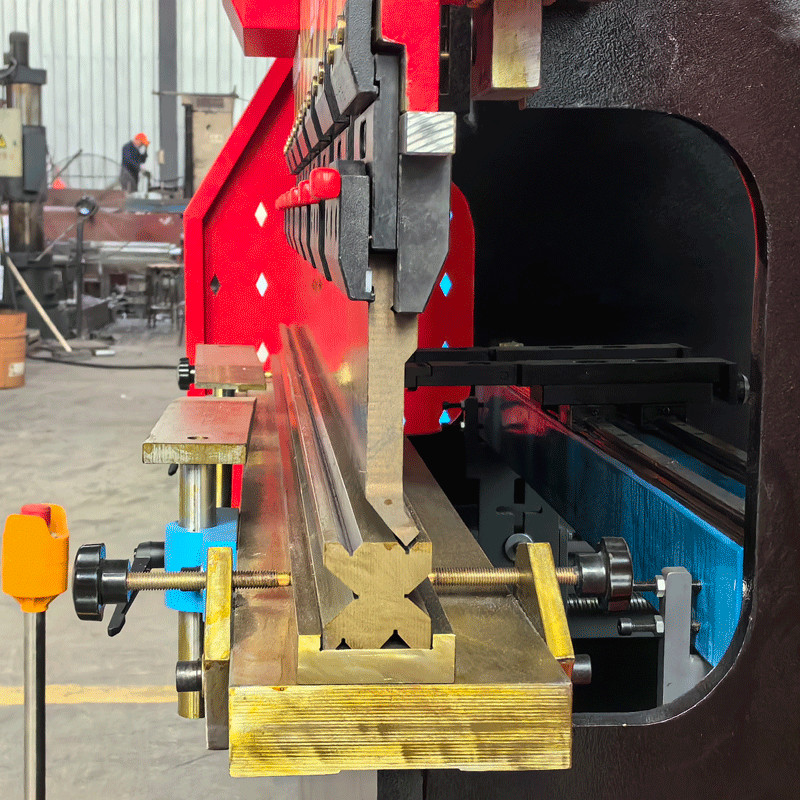

Quick mold clamping device (Optional)

Details:

TP10s controller fuction:

1. Angle programming (input how many degrees, how many degrees will

be bent out)

2. Multi-step programming (products are formed in one go)

3. Mold library

4. Product library

5. The opening height of each step is programmable

6. Support R-axis servo lifting (optional function)

7. Support Y1-Y2 dual servo drive (optional function)

8. R axis with safety distance to prevent mold collision

9. Support manual movement of gears left and right (optional

function)

10. Supports magnetic scale and can input opening height (standard

configuration)

11. Support electromechanical compensation workbench (optional

function)

12. Support large arc function

13. Supports step change conditions and bottom dead center step

change

14. Support electromagnet simple bridge (optional function)

15. Supports fully automatic pneumatic dragging bridge (optional

function)

16. Support material library, plate length, plate thickness, etc.

17. Supports functions such as frame strength and concessions

18. Support list viewing function

19. Support line-to-line pause at variable speed

Technical Parameters:

| Model | Nominal pressure (KN) | Worktable Length (mm) | Columns Distance (mm) | Throat | Slider | Max | Main | Dimension |

| Depth | Stroke | Open | motor | L x W x H |

| (mm) | (mm) | height | Power | (mm) |

| | (mm) | (KW) | |

| WC67Y/K-30/1600 | 300 | 1600 | 1280 | 200 | 80 | 190 | 3 | 1700×900×1650 |

| WC67Y/K-30/2000 | 300 | 2000 | 1280 | 200 | 80 | 190 | 3 | 1700×900×1650 |

| WC67Y/K-40/2500 | 400 | 2500 | 1900 | 280 | 100 | 320 | 5.5 | 2600×1100×1900 |

| WC67Y/K-63/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 5.5 | 3100×1450×2050 |

| WC67Y/K-80/3200 | 800 | 3200 | 2700 | 350 | 170 | 380 | 7.5 | 3500×1550×2100 |

| WC67Y/K-100/3200 | 1000 | 3200 | 2700 | 400 | 200 | 420 | 7.5 | 3500×1580×2400 |

| WC67Y/K-160/3200 | 1600 | 3200 | 2700 | 400 | 200 | 420 | 11 | 3500×1650×2550 |

| WC67Y/K-200/3200 | 2000 | 3200 | 2700 | 400 | 200 | 420 | 15 | 3500×1680×2550 |

| WC67Y/K-250/3200 | 2500 | 3200 | 2700 | 400 | 200 | 420 | 15 | 3500×1700×2600 |

| WC67Y/K-320/3200 | 3200 | 3200 | 2700 | 400 | 200 | 420 | 22 | 3500×1800×2730 |

| WC67Y/K-400/4000 | 4000 | 4000 | 3500 | 500 | 320 | 600 | 30 | 4300×2450×3500 |

| WC67Y/K-500/5000 | 5000 | 5000 | 3900 | 500 | 320 | 600 | 37 | 5400×2810×4300 |

| WC67Y/K-500/6000 | 5000 | 6000 | 4900 | 500 | 320 | 600 | 37 | 6500×2810×4300 |

| WC67Y/K-500/7000 | 5000 | 7000 | 4900 | 500 | 320 | 600 | 37 | 7500×2810×4900 |

| WC67Y/K-600/5000 | 6000 | 5000 | 3900 | 500 | 320 | 600 | 45 | 5500×2910×4900 |

Packing Detail:

Each Hydraulic Press Brake with plastic film package first, then

placed in a wooden case, wooden case with a foam filling.

We loaded the truck with heavy trucks for loading the cargo to the

harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail:

Shipped in 30 days after payment

Our Service

1.Training Service

Our technician is available to your factory and offer training of

how to use our machines. As well, you may send your technician to

our company to learn how to operate machines.

2. Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and

working performance is the same as the data of samples making). We

sign the agreement with detailed technical data.

We arrange final test before shipment. We run the machine for a few

days, and then use customer's materials for test. After making sure

machine is the best performance, then make shipments.

Our workshop:

FAQ:

1. Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of

Analysis/Conformance: Insurance: Origin, and other export documents

where required.

2. What is the average lead time?

For samples the lead time is about 7 days. For mass production the

lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your

deposit and (2) we have your final approval for your products. If

our lead times do not work with your deadline, please go over your

requirements with your sale. In all cases we will try to

accommodate your needs. In most cases we are able to do so.

3. What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or

Alipay:30% deposit in advance, 70% balance before shipment.

4. What is the product warranty?

The warranty period is 13 months after the bill of lading date. We

warranty our materials and workmanship. Our commitment is to your

satisfaction with our products. In warranty or not, it is the

culture of our company to address and resolve all customer issues

to everyone's satisfaction.

5. Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use

specialized hazard packing for dangerous goods and validated cold

storage shippers for temperature sensitive items. Specialist

packaging and non-standard packing requirements may incur an

additional charge.

6. How about the shipping fees?

The shipping cost depends on the way you choose to get the goods.

Express is normally the quickest but also most expensive way. By

seafreight is the best solution for big amounts. Exactly freight

rates we can only give you if we know the details of amount, weight

and way. Please contact us for further information.

7.Are you a manufacturer? Can we come and visit your factory?

Yes, we are manufacturer. You are welcome to visit the factory, and

we will introduce the products you are interested in in detail on

the spot.

Contact information: